|

ENGINEERING |

||||

|

This Web page: PAST PROJECTS |

| CONTACT RAS |

CUSTOMER: WOELKE MAGNETBANDTECHNIK (Germany)

PROJECT:Design and build a factory to produce magnetic head

suspensions from coiled steel to finished product. Totally different than

the Seagate factory.

SUMMARY: RAS built a complete factory in 16 months from blank pieces of

paper. Including a fully automated NdYag laser welder (2000 parts/hr)-automated

forming and automated gram load adjusting-all electrical and software

was from scratch.

PROJECT:Design and build a factory to produce magnetic head suspensions.

SUMMARY: RAS built a complete factory in 9 months from blank pieces of paper. Including a automated NdYag laser welder (1000 parts/hr)-automated forming and automated gram load adjusting-all electrical and software was from scratch. The price of a suspension went from $2.10 to $.70 world wide after completion of this project.

PROJECT:Design and build a next generation blood analysis diagnostic insturment that has an integral automated sample loader.

SUMMARY: RAS built a prototype of the instrument first and then the automated sample loader using 3D CAD. Abbott was responsible for the technology flow panel and software. This project schedule was about 18 months.

PROJECT: Assist Apple with the implementation of the Apple IIC

SUMMARY: RAS assisted Apple with respect to the product design implementation. RAS worked under the direction of Apple's Industrial Design and solved numerous problems with respect to construction and tooling.

PROJECT:Design and build a new concept diffraction grating controller in liquid chromotography by adapting standard disk drive technology.

SUMMARY: RAS built a prototype that achieved the required scanning accuracy of .0002 degrees over 20 ms. Patent # 5,488,240

PROJECT:Develop the manufacturing technology to automatically align and hermetically seal photo diodes and photo transistors in their respective packages.

SUMMARY: RAS designed and built a technology demonstrator that met the above specifications with respect to proof of concept.

PROJECT: Concept, design and build the structure for MCREWS (Modular Covert Remote Electronic Warfare Simulator).

SUMMARY: RAS subcontracted to Radio Design Group and CSC and supported this project. The four RAS prototypes were used to prove the concept at EPG (Army Electronic Proving Ground). MCREWS simulates open air jamming (with no open air radiation) of the system under test and records the results for later analysis.

EMPLOYER: FAIRCHILD CAMERA AND INSTRUMENT

US PATS -- 4,352,492 -- 4,095,791 -- 4,085,301

PROJECT:Design, tool and put into production the WORLDS

FIRST PROGRAMMABLE VIDEO GAME with individual cartridges and

hand controllers.

SUMMARY: This was the last employment of Mr Smith before starting Ronald

A. Smith and Associates Inc. in 1978. This project was started in March

and prototypes were first working 9 minutes before being photographed

by Newsweek in June (90 days).

PROJECT:Design, tool and put into production a complete product line of hand held and printing calculators.

SUMMARY: As Mechanical Engineering Manager Mr. Smith implemented 80% of Novus' calculator product line during its start up period.

PROJECT:Design and tool the words first after market video cartridge.

SUMMARY: Four individuals came to RAS and asked if a video cartridge could be designed to interface with the Atari 2600 video game and get around the patents. They handed me the patents and 1 week later I said that I could. They left Atari and formed a new company that had no name at that time. The Activision name was selected during the product design phase.

PROJECT:Design, tool and put into production the first hand held language.

SUMMARY: RAS designed the structure and a unique memory cartridge. Also RAS worked with LNP to develop semiconducting plastic to dissipate static charge from the memory module and protect the 24 pin DIP memory. RAS also spent two weeks in Hong Kong supervising final tooling first article sampling.

PROJECT:Design and build a peristaltic pump technology demonstrator from customer concept sketches.

SUMMARY: RAS determined that the original concept could not function as originally envisioned by the customer. A modification to the design approach to accomplish the intended function was offered by RAS and accepted by the customer. Test fixtures were designed and built to prove out the basic concept. The customer took over responsibility for production implementation.

PROJECT:Design a non contact 3D position sensor using magnetic fields

SUMMARY: RAS invented a "...new class of sensors." This ground breaking technology was first published in Sensors magazine. The sensor gives X,Y and Z positioning of a target relative to the center of the sensor. A corporation "True Position Magnetics" was formed to take this new technology to the market place.

PROJECT:Design and tool a personal computer the "Corvus Concept"

SUMMARY: RAS designed and tooled this early PC. The monitor could be used in either the vertical (shown) or horizontal orientation. The user could quickly change from one orientation to the other.

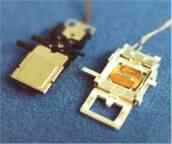

PROJECT:Design and build a servo'd floppy actuator to replace the standard actuator in a 3.5" floppy disk drive thus turning a 1.44 MB diskette into a 20 MB diskette.

SUMMARY: RAS designed and built a prototype that achieved the required 1.5 micron positional accuracy. The technology was sold to Iomega. The picture at left shows the standard actuator on the left and the new high density actuator(without a head or return path) on the right.